Posts Tagged ‘pcb plate development’

PCB Development Accurary

PCB Development Accurary

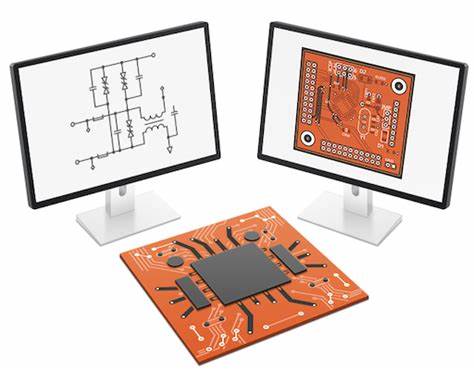

Refers to the PCB Development Accurary, depends on two aspects, one is the accuracy of the software, one for the original image accuracy. Those companies who provide circuit board development service in the current market possess broad variety of precision technical capacity, and some of them have lower accuracy of PCB reverse engineering as a result of absence of high technical ability, but some of them can reach 1mil accuracy of PCB card cloning.

There is no restriction on precision if the software apply 32-bit floating point, so the most important thing depends on the accuracy of the original scanned image, for example, if with 100 million pixels, the picture can be washed 5-inch photos, but if we want it to wash into a 20-inch photos, it simply can not see, so for a high precision circuit board is, Choosing a higher DPI is necessary and critical when scaning the printed circuit board which will help to obtain an good solution pictures.

The definition of DPI is quantity of points per inch. It simply stand for the distance between two points of the scanned image is 1mil, so if DPI is 400, then the distance between two points on the image is 1000/400 = 2.5 mil, that means the accuracy is 2.5mil.

This is the most scientific measurement way, although some people claim the accurary can below 1mil, it is a prerequisite. In fact, the pcb development accurary largely depends on the original image accuracy.

To sum up, DPI value setting on the scaning machine should be determined by the requirement level of accurary of PCB board which is ready to be developped, for instance, line spacing of mobile phone circuit board usually below 1mil, then the value of DPI need to be set at more than 1000 . Scanner on the market today can satisfy this condition.

But it is hard to say the higher DPI being set, the better PCB circuitry pattern scanning job can be done.

Since higher DPI is too large to install and process in the hardware enviroment which has much higher requirement on the hardware, so the specific settings of DPI value should be adjustable according to specific pwb and their corresponding requirement. For the PCB board schematic diagram restoration with general accuracy requirement need to generally use 400DPI is enough.