Recover MCU ATmega644 Code

Recover MCU ATmega644 Code

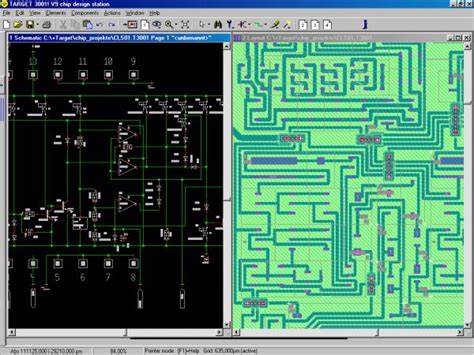

Recover MCU ATmega644 Code from secured program memory, the code of ATmega644 will be extracted by cracking ATmega644 security fuse bit;

There are several issues to consider when trying to minimize the power consumption in an AVR controlled system. In general, sleep modes should be used as much as possible, and the sleep mode should be selected so that as few as possible of the device’s functions are operating when Recover Mcu.

All functions not needed should be disabled. In particular, the following modules may need special consideration when trying to achieve the lowest possible power consumption.

If enabled, the ADC will be enabled in all sleep modes. To save power, the ADC should be disabled before entering any sleep mode. When the ADC is turned off and on again, the next conversion will be an extended conversion. Refer to “Analog to Digital Converter” on page 274 for details on ADC operation before break IC SST89E58RD2 software.

When entering Idle mode, the Analog Comparator should be disabled if not used. When entering ADC Noise Reduction mode, the Analog Comparator should be disabled. In other sleep modes, the Analog Comparator is automatically disabled after Recover MCU dspic30f6013a firmware.

However, if the Analog Comparator is set up to use the Internal Voltage Reference as input, the Analog Comparator should be disabled in all sleep modes. Otherwise, the Internal Voltage Reference will be enabled, independent of sleep mode. Refer to “Analog Comparator” on page 271 for details on how to configure the Analog Comparator.

If the Brown-out Detector is not needed by the application, this module should be turned off. If the Brown-out Detector is enabled by the BODLEVEL Fuses, it will be enabled in all sleep modes, and hence, always consume power. In the deeper sleep modes, this will contribute significantly to the total current consumption when break Mcu at89c5131a bin.

Refer to “Brown-out Detection” on page 59 for details on how to configure the Brown-out Detector.

The Internal Voltage Reference will be enabled when needed by the Brown-out Detection, the Analog Comparator or the ADC. If these modules are disabled as described in the sections above, the internal voltage reference will be disabled and it will not be consuming power.

When turned on again, the user must allow the reference to start up before the output is used. If the reference is kept on in sleep mode, the output can be used immediately. Refer to “Internal Voltage Reference” on page 62 for details on the start-up time.

If the Watchdog Timer is not needed in the application, the module should be turned off. If the Watchdog Timer is enabled, it will be enabled in all sleep modes, and hence, always consume power. In the deeper sleep modes, this will contribute significantly to the total current consumption. Refer to “Interrupts” on page 69 for details on how to configure the Watchdog Timer.

When entering a sleep mode, all port pins should be configured to use minimum power. The most important is then to ensure that no pins drive resistive loads. In sleep modes where both the I/O clock (clkI/O) and the ADC clock (clkADC) are stopped, the input buffers of the device will be disabled.

This ensures that no power is consumed by the input logic when not needed. In some cases, the input logic is needed for detecting wake-up conditions, and it will then be enabled. Refer to the section “Digital Input Enable and Sleep Modes” on page 85 for details on which pins are enabled.

If the input buffer is enabled and the input signal is left floating or have an analog signal level close to VCC/2, the input buffer will use excessive power. For analog input pins, the digital input buffer should be disabled at all times. An analog signal level close to VCC/2 on an input pin can cause significant current even in active mode.

Digital input buffers can be disabled by writing to the Digital Input Disable Registers (DIDR2, DIDR1 and DIDR0). Refer to “Digital Input Disable Register 2 – DIDR2” on page 293, “Digital Input Disable Register 1 – DIDR1” on page 273 and “Digital Input Disable Register 0 – DIDR0” on page 293 for details.

Extract Chip ATmega324PA Code

Extract Chip ATmega324PA Code

Extract Chip ATmega324PA Code from embedded program memory after unlock chip atmega324pa.

Bit 7 – PRTWI: Power Reduction TWI

Writing a logic one to this bit shuts down the TWI by stopping the clock to the module. When waking up the TWI again, the TWI should be re initialized to ensure proper operation.

Bit 6 – PRTIM2: Power Reduction Timer/Counter2

Writing a logic one to this bit shuts down the Timer/Counter2 module in synchronous mode (AS2 is 0). When the Timer/Counter2 is enabled, operation will continue like before the shutdown if recover mcu atmega164pa code.

Bit 5 – PRTIM0: Power Reduction Timer/Counter0

Writing a logic one to this bit shuts down the Timer/Counter0 module. When the Timer/Counter0 is enabled, operation will continue like before the shutdown.

Bit 4 – Res: Reserved bit

This bit is reserved bit and will always read as zero.

Bit 3 – PRTIM1: Power Reduction Timer/Counter1

Writing a logic one to this bit shuts down the Timer/Counter1 module. When the Timer/Counter1 is enabled, operation will continue like before the shutdown after reverse engineering chip atmega324 code.

Bit 2 – PRSPI: Power Reduction Serial Peripheral Interface

Writing a logic one to this bit shuts down the Serial Peripheral Interface by stopping the clock to the module. When waking up the SPI again, the SPI should be re initialized to ensure proper operation.

Bit 1 – PRUSART0: Power Reduction USART0

Writing a logic one to this bit shuts down the USART0 by stopping the clock to the module. When waking up the USART0 again, the USART0 should be re initialized to ensure proper operation.

Bit 0 – PRADC: Power Reduction ADC

Writing a logic one to this bit shuts down the ADC. The ADC must be disabled before shut down. The analog comparator cannot use the ADC input MUX when the ADC is shut down.

Bit 7..6 – Res: Reserved bits

These bits are reserved and will always read as zero.

Bit 5 – PRTIM5: Power Reduction Timer/Counter5

Writing a logic one to this bit shuts down the Timer/Counter5 module. When the Timer/Counter5 is enabled, operation will continue like before the shutdown if break microcontroller atmega324a bin.

Bit 4 – PRTIM4: Power Reduction Timer/Counter4

Writing a logic one to this bit shuts down the Timer/Counter4 module. When the Timer/Counter4 is enabled, operation will continue like before the shutdown.

Bit 3 – PRTIM3: Power Reduction Timer/Counter3

Writing a logic one to this bit shuts down the Timer/Counter3 module. When the Timer/Counter3 is enabled, operation will continue like before the shutdown.

Bit 2 – PRUSART3: Power Reduction USART3

Writing a logic one to this bit shuts down the USART3 by stopping the clock to the module. When waking up the USART3 again, the USART3 should be re initialized to ensure proper operation.

Bit 1 – PRUSART2: Power Reduction USART2

Writing a logic one to this bit shuts down the USART2 by stopping the clock to the module. When waking up the USART2 again, the USART2 should be re initialized to ensure proper operation.

Bit 0 – PRUSART1: Power Reduction USART1

Writing a logic one to this bit shuts down the USART1 by stopping the clock to the module. When waking up the USART1 again, the USART1 should be re initialized to ensure proper operation.

Break Microcontroller ATmega324A Binary

Break Microcontroller ATmega324A Binary

Break Microcontroller ATmega324A tamper resistance system and extract embedded binary from atmega324A and decrypt ATmega324A code to c level language;

When the SM2..0 bits are written to 010, the SLEEP instruction makes the MICROCONTROLLER enter Power-down mode. In this mode, the external Oscillator is stopped, while the external interrupts, the 2-wire Serial Interface, and the Watchdog continue operating (if enabled).

Only an External Reset, a Watchdog Reset, a Brown-out Reset, 2-wire Serial Interface address match, an external level interrupt on INT7:4, an external interrupt on INT3:0, or a pin change interrupt can wake up the MICROCONTROLLER. This sleep mode basically halts all generated clocks, allowing operation of asynchronous modules only if attack microcontroller pic18f66k90 heximal.

Note that if a level triggered interrupt is used for wake-up from Power-down mode, the changed level must be held for some time to wake up the MICROCONTROLLER. Refer to “External Interrupts” on page 75 for details.

When waking up from Power-down mode, there is a delay from the wake-up condition occurs until the wake-up becomes effective. This allows the clock to restart and become stable after having been stopped. The wake-up period is defined by the same CKSEL Fuses that define the Reset Time-out period, as described in “Clock Sources” on page 40.

When the SM2..0 bits are written to 011, the SLEEP instruction makes the MICROCONTROLLER enter Power-save mode. This mode is identical to Power-down, with one exception if copy PIC18F458 MICROCONTROLLER binary:

If Timer/Counter2 is enabled, it will keep running during sleep. The device can wake up from either Timer Overflow or Output Compare event from Timer/Counter2 if the corresponding Timer/Counter2 interrupt enable bits are set in TIMSK2, and the Global Interrupt Enable bit in SREG is set.

If Timer/Counter2 is not running, Power-down mode is recommended instead of Power-save mode.

The Timer/Counter2 can be clocked both synchronously and asynchronously in Power-save mode. If the Timer/Counter2 is not using the asynchronous clock, the Timer/Counter Oscillator is stopped during sleep. If the Timer/Counter2 is not using the synchronous clock, the clock source is stopped during sleep. Note that even if the synchronous clock is running in Power-save, this clock is only available for the Timer/Counter2.

When the SM2..0 bits are 110 and an external crystal/resonator clock option is selected, the SLEEP instruction makes the MICROCONTROLLER enter Standby mode. This mode is identical to Power-down with the exception that the Oscillator is kept running. From Standby mode, the device wakes up in six clock cycles after Break MICROCONTROLLER.

When the SM2..0 bits are 111 and an external crystal/resonator clock option is selected, the SLEEP instruction makes the MICROCONTROLLER enter Extended Standby mode. This mode is identical to Power-save mode with the exception that the Oscillator is kept running.

From Extended Standby mode, the device wakes up in six clock cycles. The Power Reduction Register, PRR, provides a method to stop the clock to individual peripherals to reduce power consumption. The current state of the peripheral is frozen and the I/O registers can not be read or written.

Resources used by the peripheral when stopping the clock will remain occupied, hence the peripheral should in most cases be disabled before stopping the clock. Waking up a module, which is done by clearing the bit in PRR, puts the module in the same state as before shutdown.

Module shutdown can be used in Idle mode and Active mode to significantly reduce the overall power consumption. See “Supply Current of IO modules” on page 381 for examples. In all other sleep modes, the clock is already stopped.

Reverse Engineering IC ATmega324PV Code

Reverse Engineering IC ATmega324PV Code

Reverse Engineering IC ATmega324PV to locate the fuse bit of MCU and crack ATmega324PV for embedded memory code extraction from microcontroller ATmega324PV;

These bits define the division factor between the selected clock source and the internal system clock. These bits can be written run-time to vary the clock frequency to suit the application requirements.

As the divider divides the master clock input to the MCU, the speed of all synchronous peripherals is reduced when a division factor is used. The division factors are given in Table 20.

The CKDIV8 Fuse determines the initial value of the CLKPS bits. If CKDIV8 is unprogrammed, the CLKPS bits will be reset to “0000”.

If CKDIV8 is programmed, CLKPS bits are reset to “0011”, giving a division factor of 8 at start up. This feature should be used if the selected clock source has a higher frequency than the maximum frequency of the device at the present operating conditions after Recover chip c8051f340 firmware.

Note that any value can be written to the CLKPS bits regardless of the CKDIV8 Fuse setting. The Application software must ensure that a sufficient division factor is chosen if the selected clock source has a higher frequency than the maximum frequency of the device at the present operating conditions. The device is shipped with the CKDIV8 Fuse programmed.

Sleep modes enable the application to shut down unused modules in the MCU, thereby saving power. The AVR provides various sleep modes allowing the user to tailor the power consumption to the application’s requirements after break mcu dspic30f4011 hex.

To enter any of the five sleep modes, the SE bit in SMCR must be written to logic one and a SLEEP instruction must be executed. The SM2, SM1, and SM0 bits in the SMCR Register select which sleep mode (Idle, ADC Noise Reduction, Power-down, Power- save, or Standby) will be activated by the SLEEP instruction

The MCU is then halted for four cycles in addition to the start-up time, executes the interrupt routine, and resumes execution from the instruction following SLEEP. The contents of the Register File and SRAM are unaltered when the device wakes up from sleep. If a reset occurs during sleep mode, the MCU wakes up and executes from the Reset Vector.

Recovery MCU ATmega324V Code

Recovery MCU ATmega324V Code

Recovery MCU ATmega324V Code from flash memory, the microcontroller ATmega324V code extraction will be carried out after MCU ATmega324V cracking;

The device can utilize a 32.768 kHz watch crystal as clock source by a dedicated Low Frequency Crystal Oscillator. The crystal should be connected as shown in Figure 22.

When this Oscillator is selected, start-up times are determined by the SUT Fuses and CKSEL0 as shown in Table 13 before break PIC16F716 MCU Heximal.

The calibrated internal RC Oscillator by default provides a 8.0 MHz clock. The frequency is nominal value at 3V and 25°C. The device is shipped with the CKDIV8 Fuse programmed.

See “System Clock Prescaler” on page 48 for more details. This clock may be selected as the system clock by programming the CKSEL Fuses as shown in Table when copy pic16f886 Mcu firmware

If selected, it will operate with no external components. During reset, hardware loads the calibration byte into the OSCCAL Register and thereby automatically calibrates the RC Oscillator. At 3V and 25°C, this calibration gives a frequency of 8 MHz ± 1%.

The oscillator can be calibrated to any frequency in the range 7.3 – 8.1 MHz within ±1% accuracy, by changing the OSCCAL register.

When this Oscillator is used as the mcu clock, the Watchdog Oscillator will still be used for the Watchdog Timer and for the Reset Time-out. For more information on the pre-programmed calibration value, see the section “Calibration Byte” on page 338 before attack atmega162 Mcu flash.

The device is shipped with this option selected.

The frequency ranges are preliminary values. Actual values are TBD.

If 8 MHz frequency exceeds the specification of the device (depends on VCC); The CKDIV8 Fuse can be programmed in order to divide the internal frequency by 8. When this Oscillator is selected, start-up times are determined by the SUT Fuses.

The Oscillator Calibration Register is used to trim the Calibrated Internal RC Oscillator to remove process variations from the oscillator frequency. The factory-calibrated value is automatically written to this register during mcu reset, giving an oscillator frequency of 8.0 MHz at 25°C. The application software can write this register to change the oscillator frequency.

The oscillator can be calibrated to any frequency in the range 7.3 – 8.1 MHz within ±1% accuracy. Calibration outside that range is not guaranteed.

Note that this oscillator is used to time EEPROM and Flash write accesses, and these write times will be affected accordingly. If the EEPROM or Flash are written, do not calibrate to more than 8.8 MHz. Otherwise, the EEPROM or Flash write may fail.

The CAL7 bit determines the range of operation for the oscillator. Setting this bit to 0 gives the lowest frequency range, setting this bit to 1 gives the highest frequency range.

The two frequency ranges are overlapping, in other words a setting of OSCCAL = 0x7F gives a higher frequency than OSCCAL = 0x80.

The CAL6..0 bits are used to tune the frequency within the selected range. A setting of 0x00 gives the lowest frequency in that range, and a setting of 0x7F gives the highest frequency in the range. Incrementing CAL6..0 by 1 will give a frequency increment of less than 2% in the frequency range 7.3 – 8.1 MHz.

Reverse Engineering Chip ATmega324 Code

Reverse Engineering Chip ATmega324 Code

Reverse Engineering Chip ATmega324 and extract ATmega324 mcu Code from embedded flash memory and eeprom memory, microcontroller ATmega324 can be unlocked;

The device can utilize a 32.768 kHz watch crystal as clock source by a dedicated Low Frequency Crystal Oscillator. The crystal should be connected as shown in Figure 22.

When this Oscillator is selected, start-up times are determined by the SUT Fuses and CKSEL0 as shown in Table 13. The calibrated internal RC Oscillator by default provides a 8.0 MHz clock. The frequency is nominal value at 3V and 25°C. The device is shipped with the CKDIV8 Fuse programmed.

See “System Clock Prescaler” on page 48 for more details. This clock may be selected as the system clock by programming the CKSEL Fuses as shown in Table If selected, it will operate with no external components before Recover IC AT89C4051 hex.

During reset, hardware loads the calibration byte into the OSCCAL Register and thereby automatically calibrates the RC Oscillator. At 3V and 25°C, this calibration gives a frequency of 8 MHz ± 1%.

The oscillator can be calibrated to any frequency in the range 7.3 – 8.1 MHz within ±1% accuracy, by changing the OSCCAL register. When this Oscillator is used as the chip clock, the Watchdog Oscillator will still be used for the Watchdog Timer and for the Reset Time-out. For more information on the pre-programmed calibration value, see the section “Calibration Byte” on page 338 before Recover microcontroller 430G2452 heximal.

The device is shipped with this option selected.

The frequency ranges are preliminary values. Actual values are TBD.

If 8 MHz frequency exceeds the specification of the device (depends on VCC), the CKDIV8 Fuse can be programmed in order to divide the internal frequency by 8. When this Oscillator is selected, start-up times are determined by the SUT Fuses as shown in Table 15 on page 46.

The Oscillator Calibration Register is used to trim the Calibrated Internal RC Oscillator to remove process variations from the oscillator frequency before break chip LPC2132FBD64 firmware.

The factory-calibrated value is automatically written to this register during chip reset, giving an oscillator frequency of 8.0 MHz at 25°C. The application software can write this register to change the oscillator frequency.

The oscillator can be calibrated to any frequency in the range 7.3 – 8.1 MHz within ±1% accuracy. Calibration outside that range is not guaranteed.

Note that this oscillator is used to time EEPROM and Flash write accesses, and these write times will be affected accordingly. If the EEPROM or Flash are written, do not calibrate to more than 8.8 MHz. Otherwise, the EEPROM or Flash write may fail.

The CAL7 bit determines the range of operation for the oscillator. Setting this bit to 0 gives the lowest frequency range, setting this bit to 1 gives the highest frequency range. The two frequency ranges are overlapping, in other words a setting of OSCCAL = 0x7F gives a higher frequency than OSCCAL = 0x80.

The CAL6..0 bits are used to tune the frequency within the selected range. A setting of 0x00 gives the lowest frequency in that range, and a setting of 0x7F gives the highest frequency in the range. Incrementing CAL6..0 by 1 will give a frequency increment of less than 2% in the frequency range 7.3 – 8.1 MHz.

The 128 kHz internal Oscillator is a low power Oscillator providing a clock of 128 kHz. The frequency is nominal at 3V and 25°C. This clock may be select as the system clock by programming the CKSEL Fuses to “11” as shown in Table 16.

When applying an external clock, it is required to avoid sudden changes in the applied clock frequency to ensure stable operation of the MCU. A variation in frequency of more than 2% from one clock cycle to the next can lead to unpredictable behavior.

If changes of more than 2% is required, ensure that the MCU is kept in Reset during the changes. Note that the System Clock Prescaler can be used to implement run-time changes of the internal clock frequency while still ensuring stable operation. Refer to “System Clock Prescaler” on page 48 for details.

Break Microcontroller ATmega164PV Code

Break Microcontroller ATmega164PV Code

Break Microcontroller ATmega164PV start from cracking ATmega164PV mcu security fuse bit and extract processor ATmega164PV code from flash memory and eeprom memory;

The frequency ranges are preliminary values. Actual values are TBD.

This option should not be used with crystals, only with ceramic resonators.

If 8 MHz frequency exceeds the specification of the device (depends on VCC), the CKDIV8 Fuse can be programmed in order to divide the internal frequency by 8. It must be ensured that the resulting divided clock meets the frequency specification of the device before copy chip pic16f870 program.

These options should only be used when not operating close to the maximum frequency of the device, and only if frequency stability at start-up is not important for the application. These options are not suitable for crystals after Break chip pic16f917 hex.

These options are intended for use with ceramic resonators and will ensure frequency stability at start-up. They can also be used with crystals when not operating close to the maximum frequency of the device, and if frequency stability at start-up is not important for the application.

Pins XTAL1 and XTAL2 are input and output, respectively, of an inverting amplifier which can be configured for use as an On-chip Oscillator, as shown in Figure 22. Either a quartz crystal or a ceramic resonator may be used before Break Microcontroller pic18f8722 flash.

This Crystal Oscillator is a full swing oscillator, with rail-to-rail swing on the XTAL2 output. This is useful for driving other clock inputs and in noisy environments. The current consumption is higher than the “Low Power Crystal Oscillator” on page 41. Note that the Full Swing Crystal Oscillator will only operate for Vcc = 2.7 – 5.5 volts.

C1 and C2 should always be equal for both crystals and resonators. The optimal value of the capacitors depends on the crystal or resonator in use, the amount of stray capacitance, and the electromagnetic noise of the environment. Some initial guidelines for choosing capacitors for use with crystals are given in Table 12. For ceramic resonators, the capacitor values given by the manufacturer should be used.

The operating mode is selected by the fuses CKSEL3..1 as shown in Table 11.

The frequency ranges are preliminary values. Actual values are TBD.

If 8 MHz frequency exceeds the specification of the device (depends on VCC), the CKDIV8 Fuse can be programmed in order to divide the internal frequency by 8. It must be ensured that the resulting divided clock meets the frequency specification of the device.

These options should only be used when not operating close to the maximum frequency of the device, and only if frequency stability at start-up is not important for the application. These options are not suitable for crystals.

These options are intended for use with ceramic resonators and will ensure frequency stability at start-up. They can also be used with crystals when not operating close to the maximum frequency of the device, and if frequency stability at start-up is not important for the application.

Reverse Engineering IC ATmega164V Code

Reverse Engineering IC ATmega164V Code

Reverse Engineering IC ATmega164V Code and extract MCU ATmega164V heximal from embedded program memory and data memory, clone ATmega164V code to new microcontroller.

The device is shipped with internal RC oscillator at 8.0MHz and with the fuse CKDIV8 programmed, resulting in 1.0MHz system clock. The startup time is set to maximum and time-out period enabled.

(CKSEL = “0010”, SUT = “10”, CKDIV8 = “0”). The default setting ensures that all users can make their desired clock source setting using any available programming interface if Recover IC STM32F107RCT6 code.

Any clock source needs a sufficient VCC to start oscillating and a minimum number of oscillating cycles before it can be considered stable.

To ensure sufficient VCC, the device issues an internal reset with a time-out delay (tTOUT) after the device reset is released by all other reset sources. “On-chip Debug System” on page 56 describes the start conditions for the internal reset if copy microcontroller PIC16F684 firmware.

The delay (tTOUT) is timed from the Watchdog Oscillator and the number of cycles in the delay is set by the SUTx and CKSELx fuse bits. The selectable delays are shown in Table 8. The frequency of the Watchdog Oscillator is voltage dependent as shown in “ATmega164 Typical Characteristics – Preliminary Data”.

Main purpose of the delay is to keep the AVR in reset until it is supplied with minimum Vcc. The delay will not monitor the actual voltage and it will be required to select a delay longer than the Vcc rise time. If this is not possible, an internal or external Brown-Out Detection circuit should be used after Recover chip pic16f913 binary.

A BOD circuit will ensure sufficient Vcc before it releases the reset, and the time-out delay can be disabled. Disabling the time-out delay without utilizing a Brown-Out Detection circuit is not recommended.

The oscillator is required to oscillate for a minimum number of cycles before the clock is considered stable. An internal ripple counter monitors the oscillator output clock, and keeps the internal reset active for a given number of clock cycles. The reset is then released and the device will start to execute.

The recommended oscillator start-up time is dependent on the clock type, and varies from 6 cycles for an externally applied clock to 32K cycles for a low frequency crystal.

The start-up sequence for the clock includes both the time-out delay and the start-up time when the device starts up from reset. When starting up from Power-save or Power down mode, Vcc is assumed to be at a sufficient level and only the start-up time is included.

Pins XTAL1 and XTAL2 are input and output, respectively, of an inverting amplifier which can be configured for use as an On-chip Oscillator, as shown in Figure 22. Either a quartz crystal or a ceramic resonator may be used.

This Crystal Oscillator is a low power oscillator, with reduced voltage swing on the XTAL2 output. It gives the lowest power consumption, but is not capable of driving other clock inputs, and may be more susceptible to noise in noisy environments. In these cases, refer to the “Full Swing Crystal Oscillator” on page 43.

C1 and C2 should always be equal for both crystals and resonators. The optimal value of the capacitors depends on the crystal or resonator in use, the amount of stray capacitance, and the electromagnetic noise of the environment. Some initial guidelines for choosing capacitors for use with crystals are given in Table 9. For ceramic resonators, the capacitor values given by the manufacturer should be used.

Recover MCU ATmega164PA Code

Recover MCU ATmega164PA Code

Recover MCU ATmega164PA Code from secured flash memory of Microcontroller ATmega164PA and then clone the firmware of ATmega164PA processor;

Since the external memory is mapped after the internal memory as shown in Figure 14, the external memory is not addressed when addressing the first 8,704 bytes of data space.

It may appear that the first 8,704 bytes of the external memory are inaccessible (external memory addresses 0x0000 to 0x21FF). However, when connecting an external memory smaller than 64 KB, for example 32 KB, these locations are easily accessed simply by addressing from address 0x8000 to 0xA1FF.

Since the External Memory Address bit A15 is not connected to the external memory, addresses 0x8000 to 0xA1FF will appear as addresses 0x0000 to 0x21FF for the external memory before attacking MCU protection mechanism.

Addressing above address 0xA1FF is not recommended, since this will address an external memory location that is already accessed by another (lower) address. To the Application software, the external 32 KB memory will appear as one linear 32 KB address space from 0x2200 to 0xA1FF. This is illustrated in Figure 20.

Since the External Memory is mapped after the Internal Memory as shown in Figure 14,only 56KB of External Memory is available by default (address space 0x0000 to 0x21FF is reserved for internal memory). However, it is possible to take advantage of the entire External Memory by masking the higher address bits to zero.

This can be done by using the XMMn bits and control by software the most significant bits of the address. By setting Port C to output 0x00, and releasing the most significant bits for normal Port Pin operation, the Memory Interface will address 0x0000 – 0x2FFF. See the following code examples if Restore MCU program.

Care must be exercised using this option as most of the memory is masked away. Figure 21 presents the principal clock systems in the AVR and their distribution. All of the clocks need not be active at a given time. In order to reduce power consumption, the clocks to modules not being used can be halted by using different sleep modes, as described in “Power Management and Sleep Modes” on page 51. The clock systems are detailed below.

The CPU clock is routed to parts of the system concerned with operation of the AVR core. Examples of such modules are the General Purpose Register File, the Status Register and the data memory holding the Stack Pointer. Halting the CPU clock inhibits the core from performing general operations and calculations.

The I/O clock is used by the majority of the I/O modules, like Timer/Counters, SPI, and USART. The I/O clock is also used by the External Interrupt module, but note that some external interrupts are detected by asynchronous logic, allowing such interrupts to be detected even if the I/O clock is halted.

Also note that start condition detection in the USI module is carried out asynchronously when clkI/O is halted, TWI address recognition in all sleep modes.

The Flash clock controls operation of the Flash interface. The Flash clock is usually active simultaneously with the CPU clock. The Asynchronous Timer clock allows the Asynchronous Timer/Counter to be clocked directly from an external clock or an external 32 kHz clock crystal.

The dedicated clock domain allows using this Timer/Counter as a real-time counter even when the device is in sleep mode. The ADC is provided with a dedicated clock domain. This allows halting the CPU and I/O clocks in order to reduce noise generated by digital circuitry.

This gives more accurate ADC conversion results. The device has the following clock source options, selectable by Flash Fuse bits as shown below. The clock from the selected source is input to the AVR clock generator, and routed to the appropriate modules.

Break Chip ATmega164A Code

Break Chip ATmega164A Code

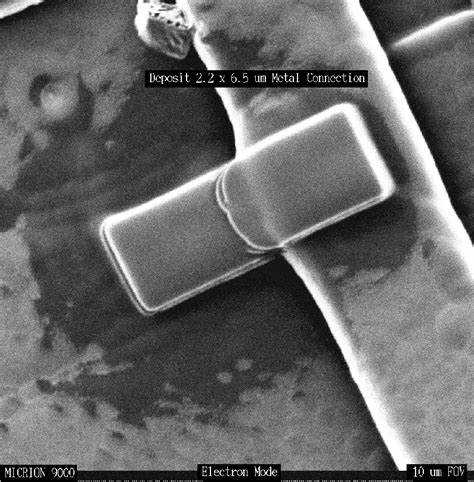

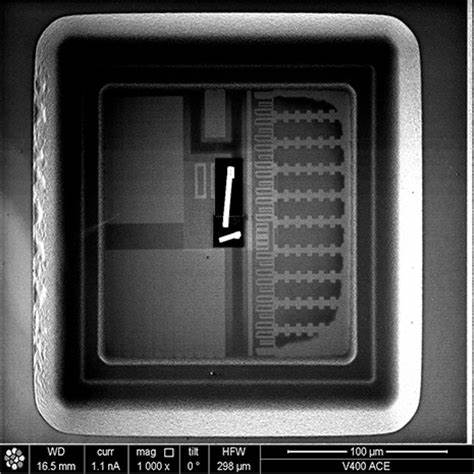

Break Chip ATmega164A protective system and extract microcontroller ATmega164A Code from flash memory, the ATmega164A MCU unlocking process will be carried out by focus ion beam;

External Memory devices have different timing requirements. To meet these requirements, the XMEM interface provides four different wait-states as shown in Table 5. It is important to consider the timing specification of the External Memory device before selecting the wait-state.

The most important parameters are the access time for the external memory compared to the set-up requirement. The access time for the External Memory is defined to be the time from receiving the chip select/address until the data of this address actually is driven on the bus if Break microcontroller s3f9454 software.

The access time cannot exceed the time from the ALE pulse must be asserted low until data is stable during a read sequence (See tLLRL+ tRLRH – tDVRH in Tables 169 through Tables 176 on pages 376 – 378).

The different wait-states are set up in software. As an additional feature, it is possible to divide the external memory space in two sectors with individual wait-state settings.

This makes it possible to connect two different memory devices with different timing requirements to the same XMEM interface. For XMEM interface timing details, please refer to Table 169 to Table 176 and Figure 161 to Figure 164 in the “External Data Memory Timing” on page 376 after read mcu pic16f688 software.

Note that the XMEM interface is asynchronous and that the waveforms in the following figures are related to the internal system clock. The skew between the internal and external clock (XTAL1) is not guarantied (varies between devices temperature, and supply voltage). Consequently, the XMEM interface is not suited for synchronous operation.

Bit 7 – SRE: External SRAM/XMEM Enable

Writing SRE to one enables the External Memory Interface.The pin functions AD7:0, A15:8, ALE, WR, and RD are activated as the alternate pin functions. The SRE bit overrides any pin direction settings in the respective data direction registers. Writing SRE to zero, disables the External Memory Interface and the normal pin and data direction set-tings are used.

Bit 6..4 – SRL2:0: Wait-state Sector Limit

It is possible to configure different wait-states for different External Memory addresses. The external memory address space can be divided in two sectors that have separate wait-state bits. The SRL2, SRL1, and SRL0 bits select the split of the sectors, see Table 4 and Figure 14.

By default, the SRL2, SRL1, and SRL0 bits are set to zero and the entire external memory address space is treated as one sector. When the entire SRAM address space is configured as one sector, the wait-states are configured by the SRW11 and SRW10 bits.

Bit 7– XMBK: External Memory Bus-keeper Enable

Writing XMBK to one enables the bus keeper on the AD7:0 lines. When the bus keeper is enabled, AD7:0 will keep the last driven value on the lines even if the XMEM interface has tri-stated the lines. Writing XMBK to zero disables the bus keeper. XMBK is not qualified with SRE, so even if the XMEM interface is disabled, the bus keepers are still activated as long as XMBK is one.

Bit 6..3 – Res: Reserved Bits

These bits are reserved and will always read as zero. When writing to this address location, write these bits to zero for compatibility with future devices.

Bit 2..0 – XMM2, XMM1, XMM0: External Memory High Mask

When the External Memory is enabled, all Port C pins are default used for the high address byte. If the full 60KB address space is not required to access the External Memory, some, or all, Port C pins can be released for normal Port Pin function as described in Table 6. As described in “Using all 64KB Locations of External Memory” on page 36, it is possible to use the XMMn bits to access all 64KB locations of the External Memory.